Process

Our products are created using innovative freeze dry technology. In simple terms, freeze drying is a dehydration process where water is removed from ingredients by using a low temperature vacuum.

No worries, it’s perfectly safe! Freeze dry technology has been around for a while and early uses were for aerospace and military medication & food because of its high production costs.

Today, it’s mainly used in the pharmaceutical industry for products like antibiotics, protein, hormones, viruses and collagen sponges for transplants. Food wise, you might see it used for things like vitamins, vegetables, herbs and milk derivatives.

Now, we’re bringing its benefits to you in the beauty space – in an easy to take and affordable way.

Did you

Know?

Freeze dry technology was used by NASA in the 50s and 60s for food. Astronauts needed meals that were easy to prepare and rehydrate, light enough to transport but still appetising and nutritious. After extensive testing into different process methods, they found that freeze drying was the one that ticked all these boxes.

Freeze dry technology has also been used in WWII for penicillin.

Making

All procedures are under the 40°C

While freeze drying is not the most economic or quickest production process out there, our results from over 3 years of research and over 1000 product trials really have proven that it’s the ideal process for supplements.

Unlike conventional manufacturing methods, our products take a long time to make and require a very specific and careful selection of ingredients and quantities to achieve that deliciously satisfying melt-in-your-mouth experience.

Pre-mixing

Dry and wet materials are mixed together for 1 hour.

Mixing

The mixing process continues for another 2 hours. We’ve found that water soluble ingredients are best to use for even consistency

Adding air

TAir is added in at 300kg/hr to produce that fluffy, melt-in- your-mouth sensation.

Molding

When the product paste has the right consistency to create an even surface, they are shaped to size at 150kg/hr.

Pre-freezing

Our product molds are then rapidly frozen at –40°C for 4 to 5 hours to preserve all the goodness and keep in the air.

Freeze drying

We remove all the water in the last freeze dry stage which takes 24 hours. This is why our recipes are formulated with little to no ingredients that have strong water- binding abilities such as sugars.

Pre-mixing

Dry and wet materials are mixed together for 1 hour.

Mixing

The mixing process continues for another 2 hours. We’ve found that water soluble ingredients are best to use for even consistency

Adding air

TAir is added in at 300kg/hr to produce that fluffy, melt-in- your-mouth sensation.

Molding

When the product paste has the right consistency to create an even surface, they are shaped to size at 150kg/hr.

Pre-freezing

Our product molds are then rapidly frozen at –40°C for 4 to 5 hours to preserve all the goodness and keep in the air.

Freeze drying

We remove all the water in the last freeze dry stage which takes 24 hours. This is why our recipes are formulated with little to no ingredients that have strong water- binding abilities such as sugars.

Why Us?

There are many reasons to love Vmores. Here’s some of them:

Proudly Australian

We’re Australian made and owned. Our products use at least 70% Australian ingredients.

Long shelf-life

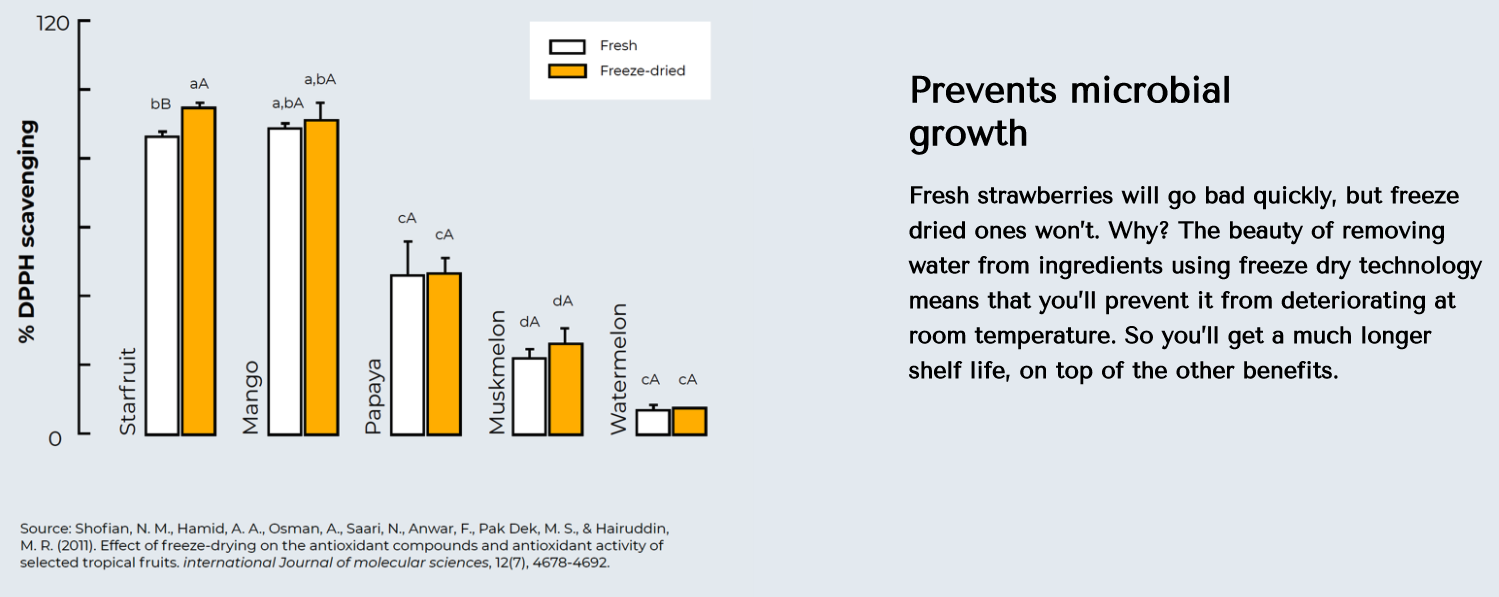

Freeze drying removes water which stops deterioration at room temperature, meaning our products have up to 2 years shelf life.

Fun to eat

Enjoy a delicious blend of fruit and yoghurt flavours, with a soft, crispy texture that melts in your mouth.

Nutrients 101

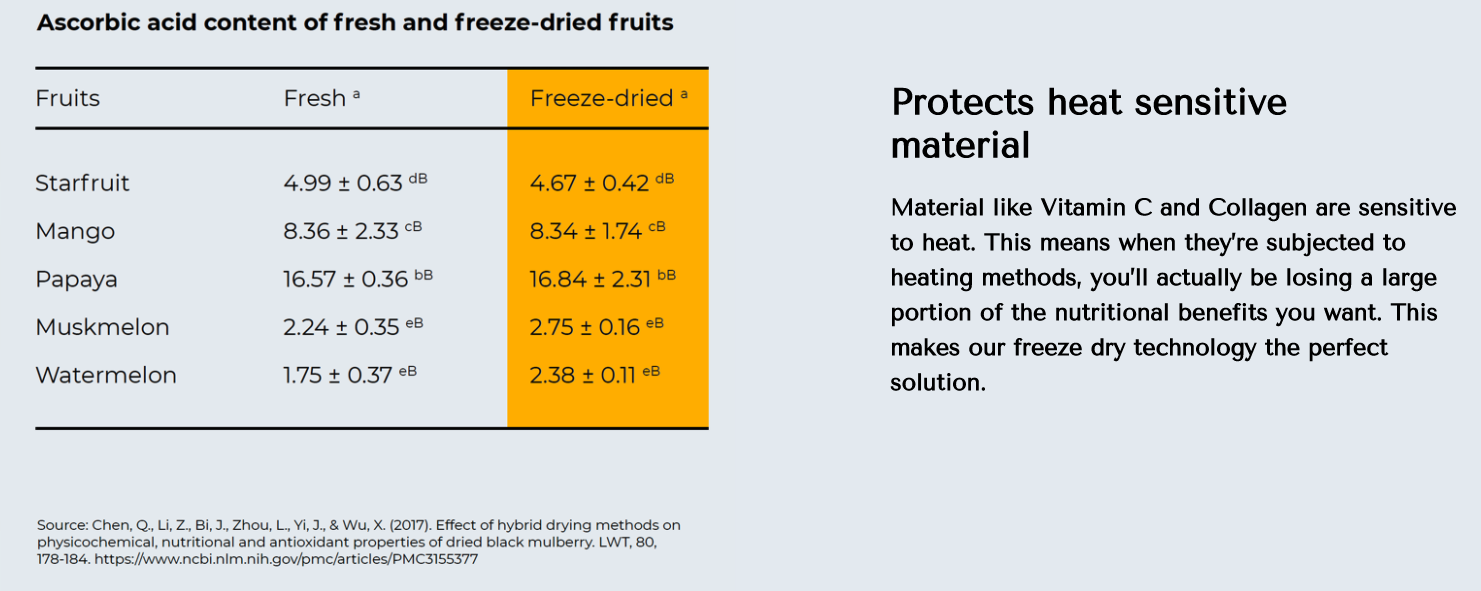

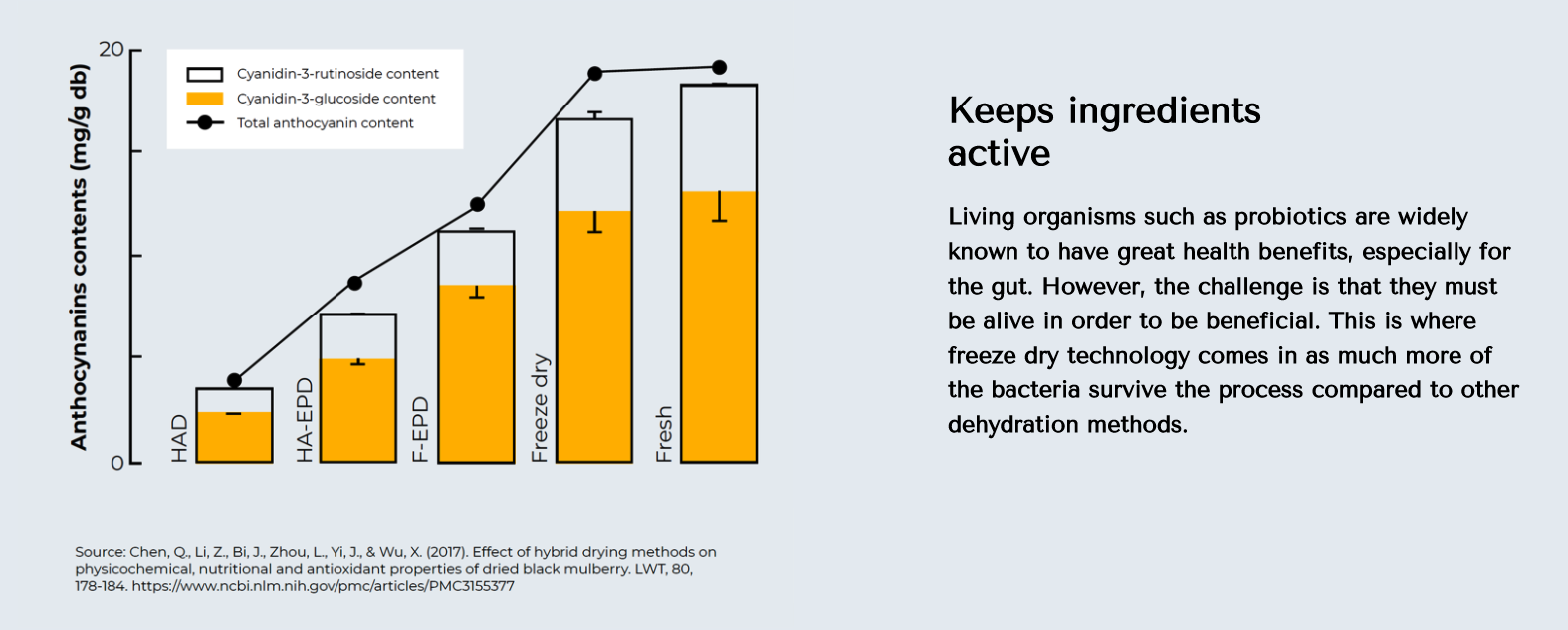

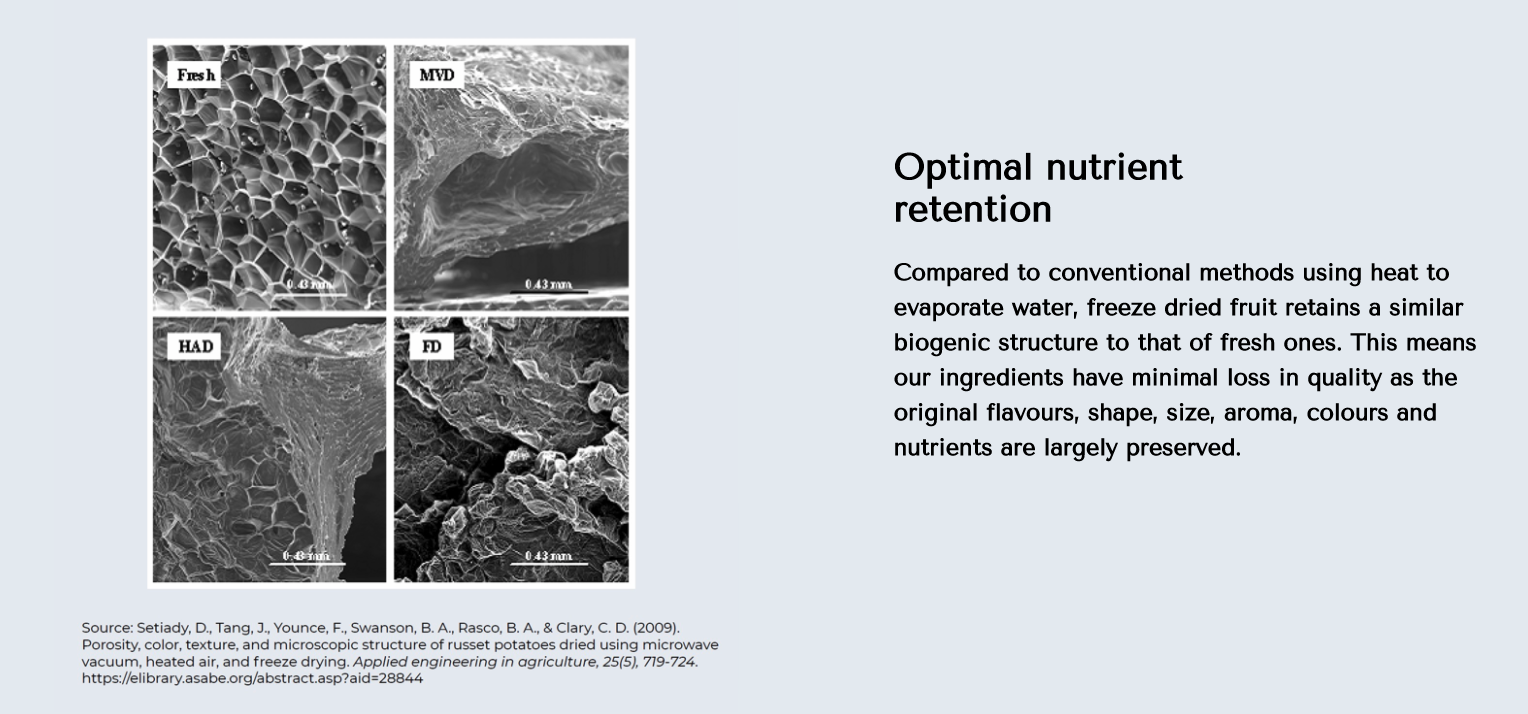

Freeze dry technology keeps 95–100% of the ingredient nutrients locked in (comparable to fresh fruit) so you’ll get all the benefits.

No nasties

We don’t use preservatives or add sugar, artificial colours or flavours.

No fuss

Not your traditional supplement. No pills to swallow. No water or milk needed. Simply pop a pack open and enjoy. Easy.

Anytime, anywhere

Freeze drying removes water from ingredients, which means Vmores is super light and easy to carry around.

All natural

The taste, aroma and colours come naturally from the fresh fruit we use, sourced right here in Australia.